Video

Established in 2024 November, Pavona Coating Sdn Bhd , to streamline production lead times and strengthen our end-to-end delivery of external façade screening solutions, particularly Aluminium Series PS Profiled Screen.

As powder coating is essential to enhance durability, performance, and long-term longevity, having a powder coating right next to its door allows us to maintain tighter control over quality, scheduling, and turnaround time.

🔧 1. Superior Durability for Outdoor Exposure

Powder coating forms a hard, continuous protective layer on aluminium that resists:

-

UV radiation (prevents fading & chalking)

-

Rain, humidity, and moisture ingress

-

Corrosion and oxidation

-

Scratches and surface abrasion

👉 This makes it ideal for high-rise façades, louvers, screens, fins, and cladding exposed year-round.

☀️ 2. Excellent UV & Colour Stability

Architectural-grade powder coatings (e.g. PEF / Super Durable / PVDF-equivalent) are engineered to:

-

Maintain colour consistency for years

-

Resist yellowing and dullness

-

Meet façade warranties (10–25 years depending on system)

This is critical for corporate façades where brand colour integrity matters.

🌧️ 3. Strong Corrosion Protection (Especially on Aluminium)

Aluminium already resists corrosion — powder coating enhances this natural advantage by:

-

Sealing the surface from moisture and pollutants

-

Protecting cut edges and folds

-

Performing well in coastal, industrial, and urban conditions

With proper pretreatment (chromate / chrome-free conversion), it significantly extends façade lifespan.

🎨 4. Vast Design & Aesthetic Flexibility

Powder coating offers designers:

-

Solid colours, metallics, matt, satin & gloss finishes

-

Textured finishes (fine sand, wrinkled, anodic-look)

-

Woodgrain & stone-effect sublimation

-

Custom colour matching (RAL / bespoke)

👉 Perfect for architectural expression without compromising performance.

🌱 5. Environmentally Friendly Choice

Compared to liquid paint, powder coating is:

-

Solvent-free (zero VOCs)

-

Recyclable overspray (up to 95% reuse)

-

Lower environmental impact during application

This supports GBI, LEED, and ESG objectives increasingly required in modern developments.

🛠️ 6. Low Maintenance & Lifecycle Cost

For building owners:

-

No peeling, flaking, or blistering

-

Easy cleaning with water & mild detergent

-

No repainting required for many years

➡️ Lower maintenance = better long-term ROI, especially for high-rise façades where access is costly.

🔥 7. Compatible with Non-Combustible Façade Systems

Powder-coated aluminium:

-

Remains non-combustible

-

Suitable for façade screens, air-cond ledges, and rainscreen systems

-

Compatible with fire-safety requirements when paired with compliant substrates

With the approval and support of Jotun as an authorised applicator, Pavona Coating now provides dedicated powder-coating services exclusively aligned with your project requirements. This strategic integration enables us to serve our clients more efficiently by significantly reducing reliance on external applicators.

Following more than a year of focused research, development, and operational refinement, our coating operations have reached a mature and reliable stage, capable of handling a wide range of powder-coating applications. As a result, our lead time has been successfully reduced from the conventional 10–14 days to an accelerated 3–7 days, delivering faster project execution without compromising on quality.

Powder Coating PROMO and SPECIAL DEAL

POWDER COATING ALUMINIUM PROFILE SCREEN

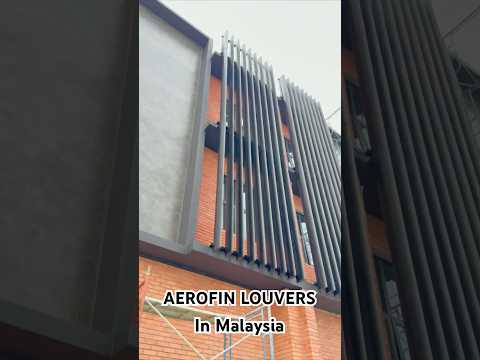

ALUMINIUM AEROFOIL (CUSTOM-MADE LOUVERS)

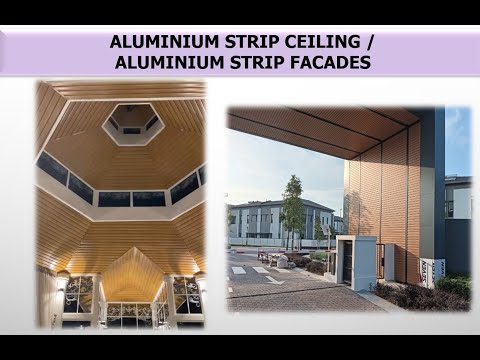

ALUMINIUM STRIP CEILING

Woodgrain Powder Coated on Aluminium Louvers

SP.ace INTRODUCTORY VIDEO